Types of Shale Shaker

Solids Control Shale Shaker

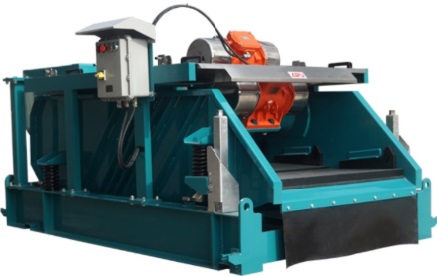

Our equipment for solids control, separation, and conveyance, recently released its dual-mode shale shaker.

Compared to single mode (either linear or elliptical ), this new style of shale shaker is capable of providing linear or elliptical vibration mode for shale shakers.

Linear vibration mode is suitable to handle hard solids such as drilling cuts. In this mode there are strong G force generated at short time interval which can effectively remove liquid on the surface of solids.

Elliptical vibration mode is more tuned to soft solids which is easy to break into smaller pieces and prone to clog shaker screens, such as the drilling of shallow sections of a well. It is a technical challenge to manufacture dual vibration mode. Solids Control Shale Shaker has been widely used in different industries, for more than 13 years.

Advantages:

1. High quality. The best material in the market and the most advanced technology has been used and its shaking basket is made of stainless steel, effectively preventing corrosion from drilling fluid. The whole shaker basket was treated using a special technique to release tension inside the basket. Automatic cutting (plasma and laser) ensures the accuracy of material pieces and automatic welding provides outstanding welding quality

2. Our Solids Control also has many other features such as shaker basket inclination adjustment, which makes basket angle adjustment an easy job.

Shale shakers are already top-of-the-line shale shakers in the market and we are looking forward to putting into advanced high-tech shale shakers.